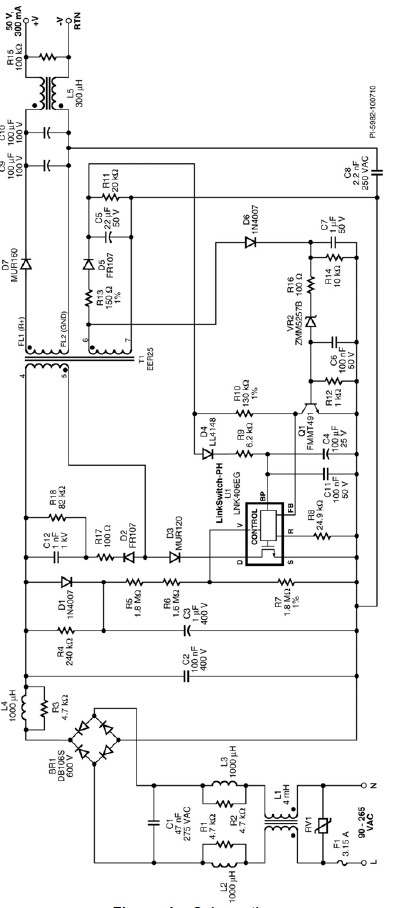

A simple led driver for T8 lamps can be designed using the LNK406EG circuit designed by Power Integrations . This Led driver circuit will drive can be used for high power LEDs pplications and it can drive a nominal LED string voltage of 50 V at 0.3 A from an input voltage range of 90 VAC to 265 VAC.

The topology used is an isolated flyback operating in continuous conduction mode.

Output current regulation is sensed entirely from the primary side eliminating the need for secondary side feedback components. The internal controller adjusts the MOSFET duty cycle to maintain a sinusoidal input current and therefore high power factor and low harmonic currents.

Fuse F1 provides protection from catastrophic component failure while RV1 (MOV)

provides a clamp to limit the maximum component voltage stress during differential line surges.

Diode bridge BR1 rectifies the AC line voltage with capacitor C2 providing a low impedance path (decoupling) for the primary switching current. A low value of capacitance (sum of C1, C2 and C3) is necessary to maintain a power factor of greater than 0.9.

EMI filtering is provided by inductors L1, L2, L3 and L4, C1 and Y1 safety rated C8.

Diode D1 and C3 detect the peak AC line voltage. This voltage is converted to a current which is fed into the V pin via R5, R6 and R7. This current is also used by the device to set the input over/under voltage protection thresholds. The V pin current and the FB pin current are used internally to control the average output LED current. The non-dimming mode of LinkSwitch was selected via a 24.9 k resistor on the R pin One end of the flyback transformer is connected to the DC bus while the other is driven by the integrated 725 V power MOSFET within U1. During the power MOSFET on time the primary current ramps up, storing energy in the transformer. This energy is transferred to the secondary when the power MOSFET turns off. An EER25 core was selected for low profile and used a triple insulated secondary winding with flying leads to meet safety spacing requirements.

Diode D3 is necessary to prevent reverse current from flowing through the LinkSwitch-PH device .

Diode D5, C5, R13 and R11 create a supply from the bias winding on the transformer.

This voltage supplies the operating current into the BYPASS pin of U1 through D4 and R9. Capacitor C4 provides local decoupling for the BYPASS pin. It is also used during startup, being charged to ~6 V from an internal high-voltage current source tied to the device DRAIN pin. Diode D6, R16, C7, R14, VR2, C6, R12, and Q1 provide an open load overvoltage

protection function.

A current proportional to the output voltage is fed into the FEEDBACK pin through R10 from the primary bias supply. This current together with the V pin current is used to maintain the average output current to be constant with changes in input and output voltage.

Diode D7 rectifies the secondary winding while capacitors C9 and C10 filter the output. A small pre-load is provided by R15 which limits the output voltage under no-load conditions and inductor L5 is used to reduce radiated EMI.